Page 254 - Green Pin Product Catalog

P. 254

Scan for

additional

product

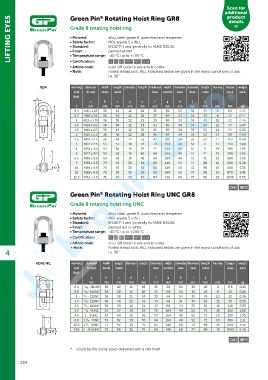

Green Pin Rotating Hoist Ring GR8

®

LIFTING EYES Grade 8 rotating hoist ring

details

alloy steel, grade 8, quenched and tempered

• Material:

MBL equals 5 x WLL

• Safety factor:

EN1677-1 and generally to ASME B30.26

• Standard:

• Finish:

painted white*

• Temperature range: -40 °C up to +200 °C

• Certification:

a

2.1 2.2 3.1 MTC

CE IIA

b

MPI

• Article code: scan QR code to see article codes

• Note: Rolled thread bolt. WLL indicated below are given in the worst conditions of use,

i.e. 90°

ADA working diameter width length diameter length thickness width diameter diameter length hex key torque weight

load thread inside inside base outside base base inside value each

limit

d

a b c d e f g h i j

d

t mm mm mm mm mm mm mm mm mm mm mm Nm kg

b

c 0.4 M8 x 1.25 36 42 12 18 35 69 34 35 43 6 6.5 0.43

b

c 0.7 M10 x 1.5 36 40 12 18 37 69 34 35 43 8 13 0.44

f 1 M12 x 1.75 36 38 12 23 39 69 34 35 43 10 22 0.46

f 1.3 M14 x 2.0 36 36 12 23 41 69 34 35 43 12 35 0.47

e 1.6 M16 x 2.0 36 43 12 28 43 69 34 35 52 14 55 0.52

i e 2 M18 x 2.5 36 41 12 28 45 69 34 35 52 14 80 0.54

g 2.5 M20 x 2.5 36 39 12 33 47 69 34 35 52 17 110 0.59

i

g 3 M22 x 2.5 53 57 19 32 70 104 49 52 71 17 150 1.88

j 4 M24 x 3.0 53 56 19 37 72 104 49 52 71 19 190 1.93

5 M27 x 3.0 53 63 19 45 64 104 49 52 71 19 280 1.96

j

6.3 M30 x 3.5 53 63 19 45 64 104 49 52 71 19 380 2.03

a h 7 M33 x 3.5 73 93 30 54 83 149 68 72 98 19 520 5.28

a h 10 M36 x 4.0 73 93 30 54 83 149 68 72 98 19 600 5.35

10 M39 x 4.0 73 93 30 63 83 149 68 72 98 19 870 5.45

12.5 M42 x 4.5 71 87 30 63 84 146 68 77 98 19 1000 5.56

CAD INFO

Green Pin Rotating Hoist Ring UNC GR8

®

Grade 8 rotating hoist ring UNC

• Material: alloy steel, grade 8, quenched and tempered

• Safety factor: MBL equals 5 x WLL

• Standard: EN1677-1 and generally to ASME B30.26

• Finish: painted red or white

• Temperature range: -40 °C up to +200 °C

• Certification: 2.1 2.2 3.1 MTC a MPI b CE IIA

• Article code: scan QR code to see article codes

• Note: Rolled thread bolt. WLL indicated below are given in the worst conditions of use,

4 i.e. 90°

ADAUNC working diameter width length diameter length thickness width diameter diameter length hex key torque weight

load thread inside inside base outside base base inside value each

limit

d

a b c d e f g h i j

d

b t mm mm mm mm mm mm mm mm mm mm mm Nm kg

c

b 0.4 5 /16 - 18UNC 36 42 12 18 35 69 34 35 43 6 6.5 0.43

c

f 0.6 3 /8 - 16UNC 36 40 12 18 37 69 34 35 43 8 13 0.44

f 1 1 /2 - 13UNC 36 38 12 24 39 69 34 35 43 10 22 0.46

e

1.7 5 /8 - 11UNC 36 43 12 31 43 69 34 35 52 13 55 0.55

i e 3

g 2.5 /4 - 10UNC 36 39 12 31 47 69 34 35 52 16 110 0.55

i

g 3.5 7 /8 - 9UNC 53 57 19 35 70 104 49 52 71 19 150 1.88

4.5 1 - 8UNC 53 54 19 41 73 104 49 52 71 19 190 1.93

j

6.8 1 /4 - 7UNC 53 62 19 55 64 104 49 52 71 19 380 2.11

1

j

10.8 1 /2 - 6UNC 73 92 30 75 83 146 68 72 98 19 600 5.55

1

a h

1

13.6 2 - 4 /2UNC 73 96 30 75 80 146 68 72 98 19 1000 6.20

a h

CAD INFO

* could be (for some sizes) delivered with a red finish

254