Page 173 - Green Pin Product Catalogue 2019_EN

P. 173

Instructions for use

Eye bolts and eye nuts should be inspected before use to ensure that:

• all markings are legible;

• an eye bolt or eye nut with the correct WLL has been selected; LIFTING EYES

• the thread is undamaged and clean;

• eye bolts and eye nuts are free from nicks, gouges and cracks;

• never grind, machine or cut an eye bolt or eye nut;

• eye bolts or eye nuts may not be heat treated as this may affect their WLL;

• never modify, repair or reshape an eye bolt or eye nut by machining, welding, heating or bending as

this may affect the WLL;

• lifting points and the other components are of the same steel grade;

• lifting points should never be side loaded (except ADA);

• always make sure that the lifting point is supporting the load correctly;

• lifting points should be seated well down in the hook;

• lifting points are not distorted or unduly worn;

• the WLL for complementary eyebolts/nuts are valid for in-line lifting only and have to be reduced for non-

axial loading. For further details please refer to the standard: DIN 580 for eye bolts or DIN 582 for eye nuts;

• the WLL for AL, OL and EL eyebolts/nuts are valid for in-line lifting only up to an angle of 30°. The WLL

decreases significantly above 30°. We recommend the use of pivoting and rotation hoist rings (ADA) when

the angle is above 30°.

• when used as a lifting device, the eye bolt or eye nut should always be fully screwed into the load in such

a way that it fits properly against the load.

Assembly

The thread length should be adapted to the material of the load. For hard materials, the thread length must

not be smaller than 1.5 times the diameter (e.g. M20, minimum length 30 mm). For soft materials such as

aluminium or brass, a length of 3 times the diameter is needed. For soft materials, consider using a longer

length and through-hole mounting with a nut and washer on the other side. The nut on the bolt should at

least be Class 8, but Class 10 or 12 is recommended.

The bolt thread and the tapped hole in the load must be compatible and both must be in a good condition.

The tapping should be at least 20% deeper than the thread length. The surface should be flat and perpendicular

to the thread to enable full contact with the lifting point.

The material to which the lifting point is attached should be strong enough to withstand lifting forces without

any deformation. The lifting points must fit perfectly on the material of the load to be lifted. Full contact

between the lifting point and the surface is required.

10

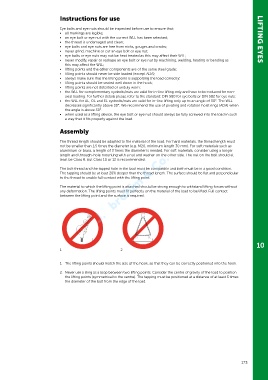

1 2

1. The lifting points should match the size of the hook, so that they can be correctly positioned into the hook.

2. Never use a sling as a loop between two lifting points. Consider the centre of gravity of the load to position

the lifting points (symmetrical to the centre). The tapping must be positioned at a distance of at least 3 times

the diameter of the bolt from the edge of the load.

173